What Is PLC (Power Line Communication)

Power Line Communication (PLC) is a data transmission technology that uses existing electrical power cables to carry communication signals.

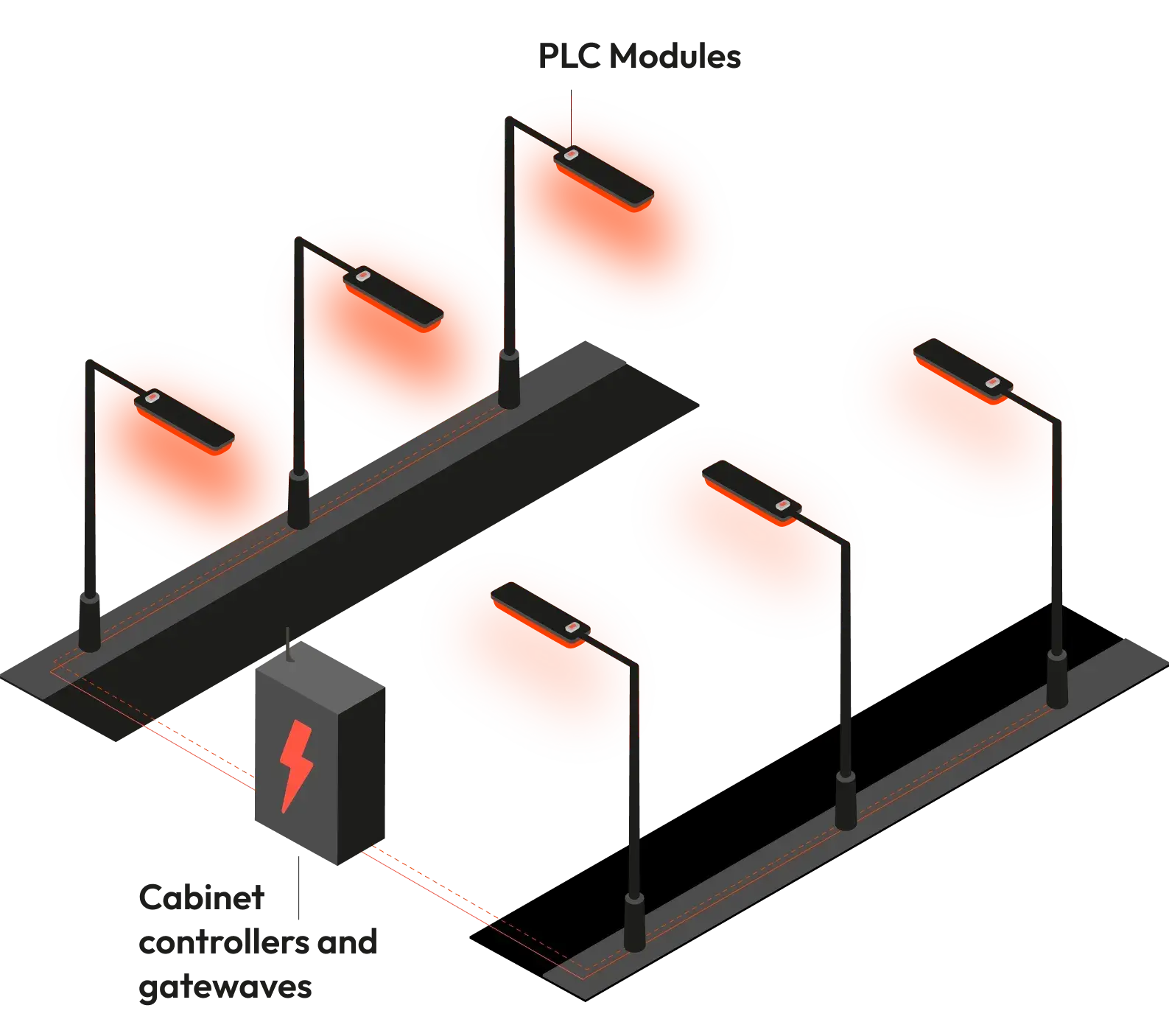

In street lighting networks, PLC allows both power and control commands to travel through the same cable that supplies luminaires, eliminating the need for additional wiring or wireless radio infrastructure.

PLC is commonly used in centralized street lighting systems where luminaires share a single feeder line and are powered from one control cabinet.

How PLC Works

PLC operates by superimposing a modulated high-frequency signal onto the standard 50/60 Hz power waveform.

The underlying voltage and frequency remain unchanged; only the waveform is modified using controlled oscillations that encode data.

A PLC-enabled luminaire includes a receiver module that:

- detects the high-frequency modulation,

- demodulates the signal,

- converts it into control commands (ON/OFF, dimming levels).

A practical analogy:

The base electrical waveform delivers energy, while the modulation layer carries data — similar to how a radio station overlays audio information on a carrier wave.

Common modulation methods in lighting PLC systems include OFDM (Orthogonal Frequency-Division Multiplexing), spread spectrum techniques, or narrowband frequency carriers.

Where PLC Is Used

PLC is technically suited for lighting networks with:

- Centralized power supply from a single cabinet,

- Long continuous feeder lines,

- Dozens or hundreds of luminaires connected to one cable,

- Lighting-only circuits without interfering electrical loads.

Typical application scenarios include:

- new urban streets,

- highways and expressways,

- industrial areas with uniform lighting infrastructure,

- large parking areas with a single supply point.

In these environments, PLC provides a cost-efficient and stable communication channel.

When PLC Cannot Be Used

PLC has practical limitations linked to electrical noise and mixed-load circuits.

The technology performs best under two conditions:

- All luminaires share one cabinet (centralized power). If multiple feeders or different power sources exist, signal continuity is disrupted.

- The power line is dedicated to lighting. Non-lighting devices introduce significant electrical noise that distorts PLC modulation.

Common sources of interference include:

- billboards and digital signage,

- traffic lights,

- public power outlets,

- pumps, compressors, motors,

- LED screens or industrial drivers.

When interference dominates the line, communication becomes unreliable.

Noise Filters and Signal Stabilization

A PLC noise filter can mitigate interference by isolating or suppressing unwanted harmonics. However, filters are not always necessary.

They are typically required only when:

- 15–20% or more of the load comes from non-lighting devices,

- the feeder includes high-interference equipment,

- the installation uses legacy devices with poor EMC characteristics.

Noise filters are not a universal requirement; they are applied selectively based on diagnostics and line conditions.

Advantages of PLC

- No additional communication infrastructure (radio or data cables not required).

- Lower installation cost due to reuse of existing power lines.

- High reliability in simple, lighting-only circuits.

- Easy deployment in linear street layouts.

- Suitable for long-distance communication over several kilometers.

Limitations of PLC

- Sensitive to electrical noise from non-lighting equipment.

- Requires that luminaires share a common electrical feeder.

- Not ideal for complex urban networks with mixed loads.

- Communication speed is lower than RF or Ethernet-based systems.

- Not suitable for highly dynamic or high-bandwidth applications.

When to Choose PLC

PLC is an appropriate control technology when:

- All lights are powered from the same cabinet.

- The feeder line has no significant third-party loads.

- A cost-efficient, stable, and simple communication method is required.

- RF communication is restricted due to regulations or interference.

- Additional cabling is impractical or too expensive.

PLC remains one of the most effective choices for uniform, centralized lighting networks.