How solar street lighting works

Why remote-controlled systems outperform traditional standalone luminaires

The segment of autonomous solar street lighting systems has been steadily growing:

According to industry research, the global solar street lighting market is expanding at a compound annual growth rate (CAGR) of approximately 7–10%. Fortune Business Insights estimates that the market will reach around $19.57 billion by 2032. This rising interest in solar lighting is easy to explain: cities and contractors aim to reduce dependency on electrical grids, lower operational expenses, and meet sustainability targets. However, practice has shown that a solar luminaire alone is not sufficient.

Without intelligent control and remote monitoring, an off-grid system faces a set of typical challenges:

- unpredictable battery depth of discharge;

- reduced energy production due to cloud cover, dust, and seasonal variations in solar irradiance;

- lack of visibility into the condition of the panel, battery, and loads;

- risk of nighttime “blackouts” during winter;

- high cost of on-site maintenance visits.

As a result, lighting quality and safety deteriorate, while OPEX increases. Against this backdrop, a new class of solutions has emerged — Solar Lighting Control Systems, which transform a standalone solar luminaire from a “black box” into a manageable and predictable infrastructure component.

The goal of this article is to explain how solar-powered street lighting control works, what operational challenges a control system solves (solar lighting battery management, remote monitoring solar lighting), and how the DITRA SOL Mini GSM and DITRA SOL Mini LiWAVE solutions help integrators, lighting manufacturers, and municipal operators build reliable and scalable projects.

How a solar street lighting system is structured and operates

A basic autonomous system (used for standalone or non-networked installations) traditionally consists of four main components:

- Solar panel (PV module)

- Charge controller (MPPT)

- Battery (typically LiFePO₄)

- LED luminaire

The energy flow is as follows: PV → MPPT charge controller → battery → LED load

However, for a scalable, predictable, and economically efficient project, a fifth key component is required — a Control and Monitoring Controller (Gateway). This device transforms a simple off-grid luminaire into a managed infrastructure asset, ensuring reliability and visibility across the entire system.

The role of the MPPT charge controller

MPPT (Maximum Power Point Tracking) is a dedicated charge controller. Its function is similar to that of a power supply unit in a computer: it operates autonomously and focuses exclusively on optimizing battery charging. It is not equipped with communication capabilities and cannot transmit operational data to a central management system.

The MPPT continuously tracks the panel’s maximum power point under real-world conditions — cloud cover, temperature fluctuations, partial shading, or dust accumulation. Studies show that MPPT controllers extract 15–25% more energy compared to simple PWM regulators under variable irradiance. For solar street lighting, this additional energy directly translates into extra nighttime operating hours and increased autonomy days.

Battery management (Solar Lighting Battery Management)

LiFePO₄ batteries are well suited for outdoor applications but require protection from:

- deep discharge,

- overcharge,

- extremely low or high temperatures,

- excessive charge/discharge currents.

A proper control system must:

- monitor SOC (State of Charge),

- forecast available energy for the upcoming night,

- adapt the lighting profile to the current energy balance.

Without battery management, system autonomy becomes unpredictable: the luminaire may perform well on clear days but disconnect prematurely during periods of poor weather.

Control and communication: The external Gateway

To obtain telemetry and remotely control the luminaire, an additional device is required — a GSM or radio-based controller, which:

- connects to the MPPT via RS-485 (Modbus), and allows remote adjustment of schedules, dimming, and lighting profiles,

- reads voltage, current, and MPPT status parameters,

- collects and decodes operational telemetry,

- transmits data to the CMS (via GSM/4G or wired Ethernet),

This external controller enables the integration of an autonomous solar luminaire into a remote monitoring and control architecture, making the system manageable and observable.

Without such a controller, a solar luminaire remains a fully autonomous “black box”, meaning the operator cannot:

- monitor system operation,

- forecast available energy,

- react to faults,

- receive alerts,

- or adjust brightness levels and schedules.

Intelligent control and diagnostics: The foundation of modern solar lighting control systems

An autonomous solar luminaire is an energy-dependent system sensitive to fluctuations in solar irradiance, panel contamination, and battery degradation.

According to published research, unfavorable weather conditions, such as a wet panel surface in cloudy weather, can cause a drop in efficiency of over 41%. Furthermore, surface contamination (dust) is shown to reduce the panel's maximum power output by approximately 35%.

Seasonal changes in the sun’s position and suboptimal panel tilt lead to significant reductions and high variability in energy production. Such fluctuation can be reliably managed and compensated only through intelligent control systems.

Telemetry as the foundation of predictability

To accurately forecast system behavior, a solar lighting controller must collect essential real-time parameters, including:

- panel and battery voltage (V+ / V−),

- charge and discharge current (I_in / I_out),

- MPPT controller status,

- load consumption (LED power),

- temperature of key components,

- error and fault codes.

This information enables the operator to:

- evaluate the actual energy balance,

- determine whether the system can operate until dawn,

- detect panel or battery degradation,

- correctly calculate expected autonomy days.

Without telemetry, system operation becomes a “blind flight”, offering no visibility into performance or risks.

Panel and battery diagnostics

An intelligent control system must not only record parameters but also interpret them. Typical diagnostic functions include:

- analyzing reductions in PV current and voltage relative to expected values,

- comparing actual power generation with theoretical irradiance,

- monitoring nighttime depth of discharge,

- identifying abnormal MPPT behavior.

This allows early detection of issues such as:

- panel contamination, shading, or physical damage;

- declining battery capacity requiring replacement (SOH — State of Health estimation based on

- discharge-cycle history);

- insufficient energy reserve that may lead to nighttime shutdowns.

In effect, the system transitions from reactive maintenance to a predictive maintenance model.

Adaptive lighting control

A solar luminaire can consume only the energy it has accumulated. Therefore, lighting control must be based on available energy rather than a fixed “100% brightness all night” approach. An intelligent solar street light controller can:

- apply nighttime step-dimming profiles,

- reduce output when battery SOC (State of Charge) is low,

- activate PIR-based boost modes only when motion is detected,

- adjust lighting schedules to seasonal conditions and expected energy production.

Why remote control is critical

Intelligent algorithms are ineffective if their results cannot be monitored, analyzed, and used in real time. Remote monitoring for solar lighting is the layer that makes the entire system operationally manageable.

From “Post-Factum” response to preventive management

Without connectivity, an operator discovers a problem only after the luminaire has already failed to turn on. Remote control allows operators to:

- see when the panel stops charging (due to contamination, shading, or damage);

- track accelerated battery degradation;

- receive alerts if the luminaire does not switch on according to schedule;

- take action before safety on the site is compromised.

Reducing OPEX and optimizing field operations

Autonomous poles are often located in remote areas, and accessing the panel or battery compartment can be labor-intensive. A service visit just to “check what happened” is costly—especially when the issue turns out to be nothing more than a dirty panel.

Remote monitoring (remote monitoring solar lighting) helps reduce the Total Cost of Ownership (TCO) by enabling:

- Optimized logistics. Service teams are dispatched only for confirmed faults, eliminating unnecessary site visits and significantly reducing maintenance workload.

- Reduced downtime. The ability to remotely reboot the system or adjust lighting profiles allows a portion of issues to be resolved without physically visiting the site.

- Extended asset lifetime. Proper solar lighting battery management, including temperature compensation and deep-discharge protection, extends the lifespan of LiFePO₄ batteries—directly improving project ROI.

For projects with dozens or hundreds of luminaires, these savings become critical to economic feasibility.

Scalability and operational transparency

A project with 5 luminaires can be managed manually. A project with 50 luminaires becomes difficult. A project with 500+ luminaires is practically unmanageable without CMS integration and remote control. A remote monitoring system provides:

- a centralized view of the entire lighting network,

- a unified interface for telemetry and fault notifications,

- a complete operational history necessary for SLA compliance and reporting to municipal authorities.

Architecturally, remote control can be implemented via GSM/4G (GSM solar lighting control) or via a radio network (wireless solar lighting control). The optimal choice depends on the project’s topology and TCO requirements.

DITRA Solutions: Solar lighting control systems

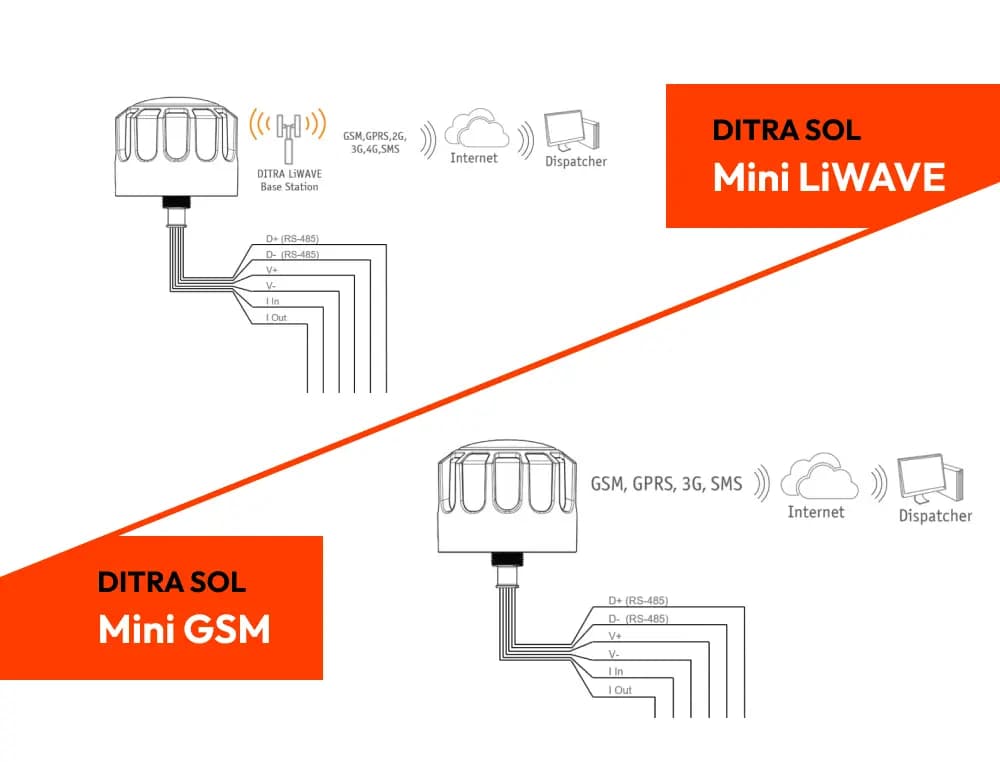

For data, diagnostics, and intelligent algorithms to become part of an operational project, a reliable controller integrated into the infrastructure is required. DITRA Solutions offers two devices for autonomous solar luminaires:

- DITRA SOL Mini GSM — a controller with direct GSM connectivity;

- DITRA SOL Mini LiWAVE — a radio-network node operating through a base station.

Both devices connect to the MPPT controller via RS-485 (Modbus) and perform three essential functions:

- Telemetry. Collecting data on battery status, PV panel performance, load consumption, current and voltage measurements.

- Diagnostics. Identifying loss of charging, detecting battery degradation, MPPT errors, and schedule-related failures.

- Control. If the MPPT supports external commands, the controller can remotely adjust brightness profiles, schedules, and operating modes of the luminaire.

For a detailed comparison of these two communication architectures (GSM vs. Radio) and a practical guide on selecting the optimal solution based on your project's topology and Total Cost of Ownership (TCO), read our dedicated article: Solar street lighting control: Choosing the right backhaul (GSM vs LiWAVE)

Control and monitoring are not “optional extras” for autonomous solar luminaires—they are essential components of any professional solar lighting project. Without an intelligent management system and remote monitoring:

- autonomous performance cannot be guaranteed, especially during winter;

- operational expenses increase due to frequent site visits;

- large-scale deployments become difficult to manage and lack transparency for the end customer.

Modern Solar Lighting Control Systems solve these challenges through telemetry, diagnostics, adaptive lighting control, and remote connectivity. DITRA SOL Mini GSM and DITRA SOL Mini LiWAVE implement all these capabilities in real-world applications, relying on principles validated by scientific research and field experience.

As a result, solar street lighting becomes not only autonomous, but predictable, manageable, and economically viable for cities, integrators, and lighting manufacturers.